Ramset’s exclusive powder pins provide easier penetration into hard steel and concrete. We maintain only the highest standards in the materials, production techniques and quality control measures used to manufacture our fasteners, assuring consistent, optimum quality in every fastener.

ADVANTAGES

Ramset maintains only the highest standards in the materials, production techniques and quality control

measures used to manufacture our fasteners, assuring consistent, optimum quality in every fastener.

BLACK PINS

The special black coating improves pin penetration into difficult base material (i.e. hard concrete). We offer this black coating on all of our fasteners manufactured for the attachment of drywall track and channel to concrete and steel.

PINS

ITW Ramset powder actuated fasteners are specifically fabricated to meet the exacting requirements of toughness and durability that enable them to penetrate dense concrete and structural quality steel.

Made from AISI 1060-1065 steel. Austempered to a core hardness of 52-56 Rc

Typical tensile strength: 270,000 psi

Typical shear strength: 162,000 psi

Standard finishes:

ICC ESR-1799 – Powder Pins & Clips

Drive pins are used to directly fasten an object (permanent installation). Threaded studs are used where the object fastened is to be removed or where shimming is required. The following shows how to determine shank and thread length. Required penetration is determined by load requirement (illustrated in the following examples). Ramset fasteners may be specified by their type or catalog number to satisfy fastening requirements.

High quality fasteners provide consistent and reliable performance in concrete, block, masonry, and steel applications. Choosing the correct fastener for the job will assure professional results.

A Determine thickness of material being attached.

B Fastener must be long enough to drive approximately 1″ into concrete, cement block or penetrate thickness of steel.

All loads are color coded and load level numbered. As the number increases, the power level increases.

Always start with the lightest load. If the fastener does not set completely, use the next higher load and repeat

the process. Click here to learn more about our powder loads.

PowerPoint Pins for Hard Concrete & Steel Fastening

Use Ramset’s exclusive PowerPoint pins for your advanced fastening applications. They provide easier

penetration into hard steel and concrete. That means reduced pin failures and increased holding values to make your jobs more productive.

Consistent Performance, in Hard Steel and Hard Concrete

Standard powder actuated pins fasten inconsistently in steel. Frequently the steel is just too hard for conventional pins. Steel is also inconsistent because hardness varies. According to the steel industry’s accepted Rockwell Hardness Scale (Rb), steel strength can vary from a relatively soft 54 Rb to an extremely hard 88 Rb or higher. Standard pins typically begin to fail in the upper 70s Rb. Tests, however, have proven that PowerPoint consistently performs, even as steel approaches 90 Rb!

Ramguard™ Drive Pins for ACQ Pressure Treated Lumber!

As many of you know, there have been changes to the regulations affecting pressure treated lumber. The industry standard CCA treated wood is no longer being produced for residential use. Most new pressure treated wood is utilizing Alkaline Copper Quaternary (ACQ) treatment. It has been confirmed that ACQ corrodes steel 2 to 4 times faster than the old CCA treated lumber. This means that our standard drive pins are not recommended for use in ACQ treated lumber. Ramset has developed a coating called Ramguard™ for use in all pressure treated wood including the new ACQ treated wood. The Ramguard coating offers excellent corrosion resistance that rivals hot dipped galvanized and stainless steel. Washered versions of these pins utilize a Ramguard coated pin and a washer with a G185 coating. This combination was developed to withstand the increased corrosion rate that sometimes occurs when using fasteners in the new treated lumber.

Pins and Loads

Ramset Powder Actuated Tools

Other Powder Actuated Tools

| Designed for use in concrete and structural steel applications. 100 per box. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| 1503K | 1/2" Knurled (12.7mm) | 50 | 5000 |

| 1506 | 3/4" (19.1mm) | 12 | 1200 |

| 1508 | 1" (25.4mm) | 12 | 1200 |

| 1510 | 1-1/4" (31.8mm) | 10 | 1000 |

| 1512 | 1-1/2" (38.1mm) | 12 | 1200 |

| 1514 | 2" (50.8mm) | 8 | 800 |

| 1516 | 2-1/2" (63.5mm) | 8 | 800 |

| 1524 | 3" (76.2mm) | 6 | 600 |

| Shank diameter = .145 Head diameter = .300 | |||

| Designed for use in concrete and structural steel applications. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| R50122 | 1-1/2" (38.1mm) | 25 | 125 |

| R50124 | 2" (50.8mm) | 25 | 125 |

| R50126 | 2-1/2" (63.5mm) | 25 | 125 |

| R50128 | Multi Pack | 200 | 1000 |

| Shank diameter = .145 Head diameter = .300 | |||

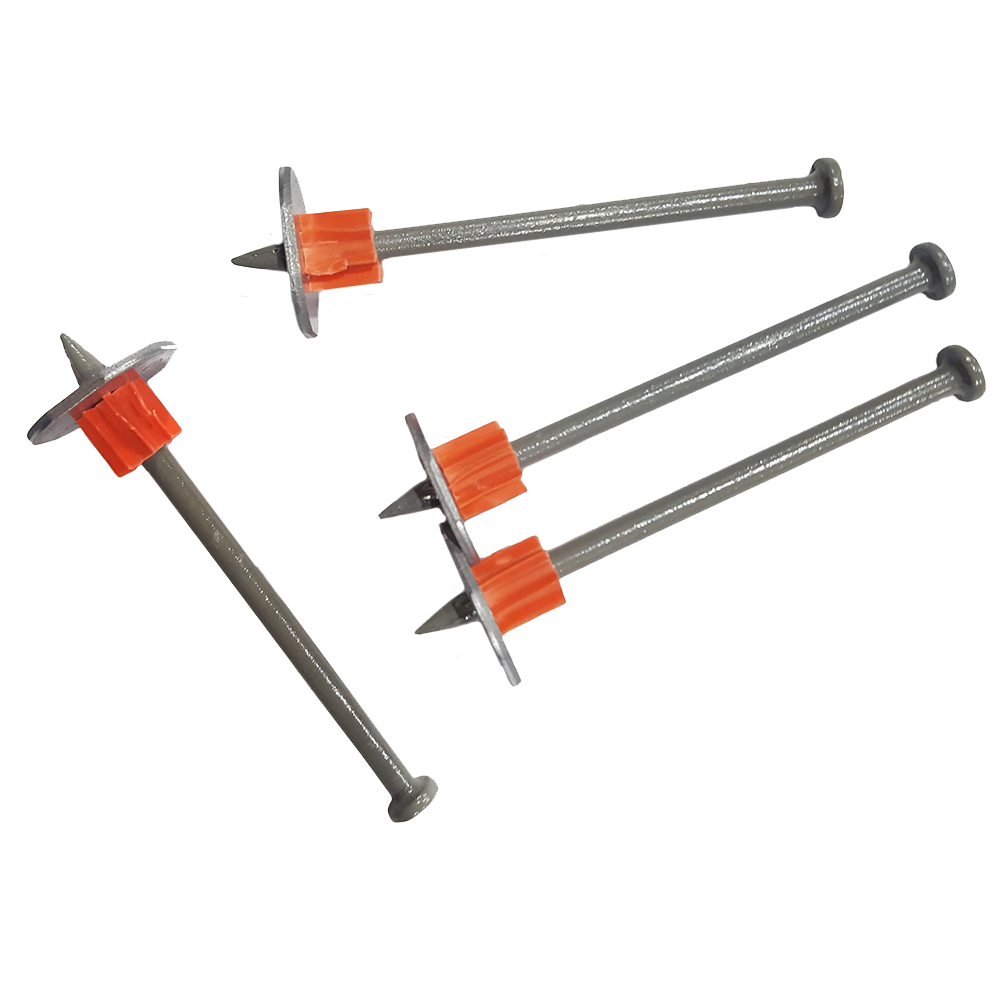

| Washer increases bearing surface against the material to be fastened. 100 per box. 16 gage metal washer. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| 1508SD | 1" (25.4mm) | 100 | 1000 |

| 1510SD | 1-1/4" (31.8mm) | 100 | 1000 |

| 1512SD | 1-1/2" (38.1mm) | 100 | 1000 |

| 1516SDC | 2-1/2" (63.5mm) | 100 | 600 |

| 1524SDP* | 3" (76.2mm) | 100 | 600 |

| Shank diameter = .145 Head diameter = .300 * Square washer indicates 3” pin has been installed. | |||

| Used for fastening into hard concrete and steel. Premium hard concrete and steel pin. 100 per box. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| SP12* | 1/2" (12.7mm) | 12 | 1200 |

| SP178 | 1-7/8" (47.6mm) | 10 | 1000 |

| Shank diameter = .150/.180 Head diameter = .300 * Shank diameter = .145, Regular PowerPoint pin without Step Shank. | |||

| Increases bearing surface against material to be fastened for improved attachment to inconsistent base materials. 100 per box. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| SP58TH | 5/8" (15.9mm) | 50 | 5000 |

| Shank diameter SP58TH and SP34TH = .150 1906 and 1908 = .145 Head diameter = .300 | |||

| Coated to improve corrosion resistance in treated lumber and other applications. 100 per box. | |||

| PART NUMBER | SHANK LENGTH IN. (MM) | BOX QTY | MASTER CASE QTY |

| 1516E | 2-1/2" (63.5mm) | 8 | 800 |

| 1524SDE* | 3" (76.2mm) | 6 | 600 |

| Shank diameter = .145 * .150/.180 Head diameter = .300 | |||

| 14 gage angle clip. 100 clips per box. | |||

| PART NUMBER | DESCRIPTION | BOX QTY | MASTER CASE QTY |

| 1202CF | Angle clip (no pin) | 100 | 100 |

| Hole diameter: 5/16" & 14/64" | |||